On February 23rd, 2024 the NISSOS KEROS ( 330 m long x 60 m wide x 17m draft ) was inbound to Europoort, dolphins 90. Pilot was hoisted onboard by

Teams Performance, The Supporting RoleTeams Performance, The Supporting Role

In The Netherlands, Maritime Pilotage is a public duty performed by a private system of pilots since 1988. The maritime pilot is an independent professional giving independent advice to a

CRUDESUN inbound to EuropoortCRUDESUN inbound to Europoort

On January 6th, 2023 the 250 m long CRUDESUN was inbound with 13m draft. Two tugs were used for bringing this lady safely alongside to Shell 103 in Europoort.

Improving Teams Performance in Pilotage WatersImproving Teams Performance in Pilotage Waters

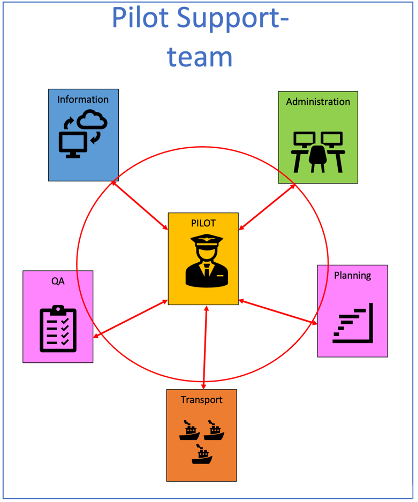

Improving Teams Performance in Pilotage Waters By: Herman Broers | February 1st, 2022 Abbreviations HCC Harbor Coordination Center VTS Vessel Traffic Service Introduction This paper aims to explore the possibilities of improving

BERGE BIMBERI to Port of RotterdamBERGE BIMBERI to Port of Rotterdam

On march 24th, 2022, the bulkcarrier BERGE BIMBERI entered Port of Rotterdam via the Eurochannel. The ship had a draft of 17,6 meters and two pilots were flown in by

The Role Of The Maritime Pilot In E-NavigationThe Role Of The Maritime Pilot In E-Navigation

Within the context of E-navigation, several concepts have been developed which could revolutionize the handling of traffic at sea and in the port. Several conditions, including the improved connectivity with

The EVER GOVERN (400m) to AmazonehavenThe EVER GOVERN (400m) to Amazonehaven

Measuring 400 meters long and with a draft of 16 meters, the EVER GOVERN came into port in December 2021. Foggy conditions and a strong SW’ly wind made it a

SAR Drill Helicopter and Pilot TenderSAR Drill Helicopter and Pilot Tender

The Netherlands pilots have a close cooperation with Noordzee Helikopters Vlaanderen (NHV) for pilot transfer operations. These helicopters are used by NL Coastguard as well. Recently, a Search and Rescue

MSC RIFAYA (400m) to seaMSC RIFAYA (400m) to sea

Short 1 minute clip of the 400 m long ULCS MSC RIFAYA from Maasvlakte2 to sea.

SHINWA MARU to EECV EuropoortSHINWA MARU to EECV Europoort

On july 1st, the 327 meters long bulk carrier SHINWA MARU entered Port of Rotterdam with 20,6 meters draft, underway to EECV terminal at the Caland channel, Europoort. Due to